Work Order Application

Project Summary

The Work Order Application is the core tool for technicians to complete services and capture critical data. In the legacy POS, work orders were static and non-editable, forcing staff to rely on manual workarounds and redundant steps. The redesign created an interactive, streamlined experience where customer, vehicle, and service details are all editable and visible in real time.

This modernized workflow reduced errors, improved efficiency, and gave technicians and sales associates a shared source of truth for service execution. With the upcoming mobile Work Order, that impact extends even further: technicians will be able to update service status, capture tread/DOT data, and complete documentation directly at the vehicle. This shift has already driven excitement in pilot stores, showing measurable improvements in speed, accuracy, and overall technician workflow.

Discover & Define

Requirements Gathering & Refinement

To ensure the Customer & Service List would meet real-world needs across store roles, we led a cross-functional effort to define and refine UX requirements before any design work began.

Initial Inputs

Existing standard operating procedures

Field trainer feedback from pilot stores

Operational pain points from the legacy POS

Business needs and KPIs

Refinement Process

Workshops with Product, Dev, Ops, and UX to map task flows and identify overlaps

Iterative requirement reviews with engineers and store experts to validate feasibility

Version-controlled documentation to keep up with shifting priorities and platform constraints

Outcome

A tightly scoped, prioritized UX requirement set that:

Aligned across business, tech, and user needs

Translated directly into design artifacts and user flows

Enabled quicker stakeholder buy-in and reduced late-stage churn

Design Challenges

Non-Editable Work Orders

Before: Technicians couldn’t directly update service data; they had to rely on handwritten notes or re-entry at checkout

Challenge: Make work orders interactive and editable without introducing errors

Poor Service Visibility

Before: Key details like tire tread, DOT codes, and replacement needs were buried or missing

Challenge: Surface critical information in one place with clear hierarchy

Error-Prone Documentation

Before: Manual entry fields increased risk of missing or inconsistent data

Challenge: Add structured inputs, smart defaults, and validation to reduce risk, while preparing for mobile workflows that allow service techs to update the work order without ever leaving the vehicle side

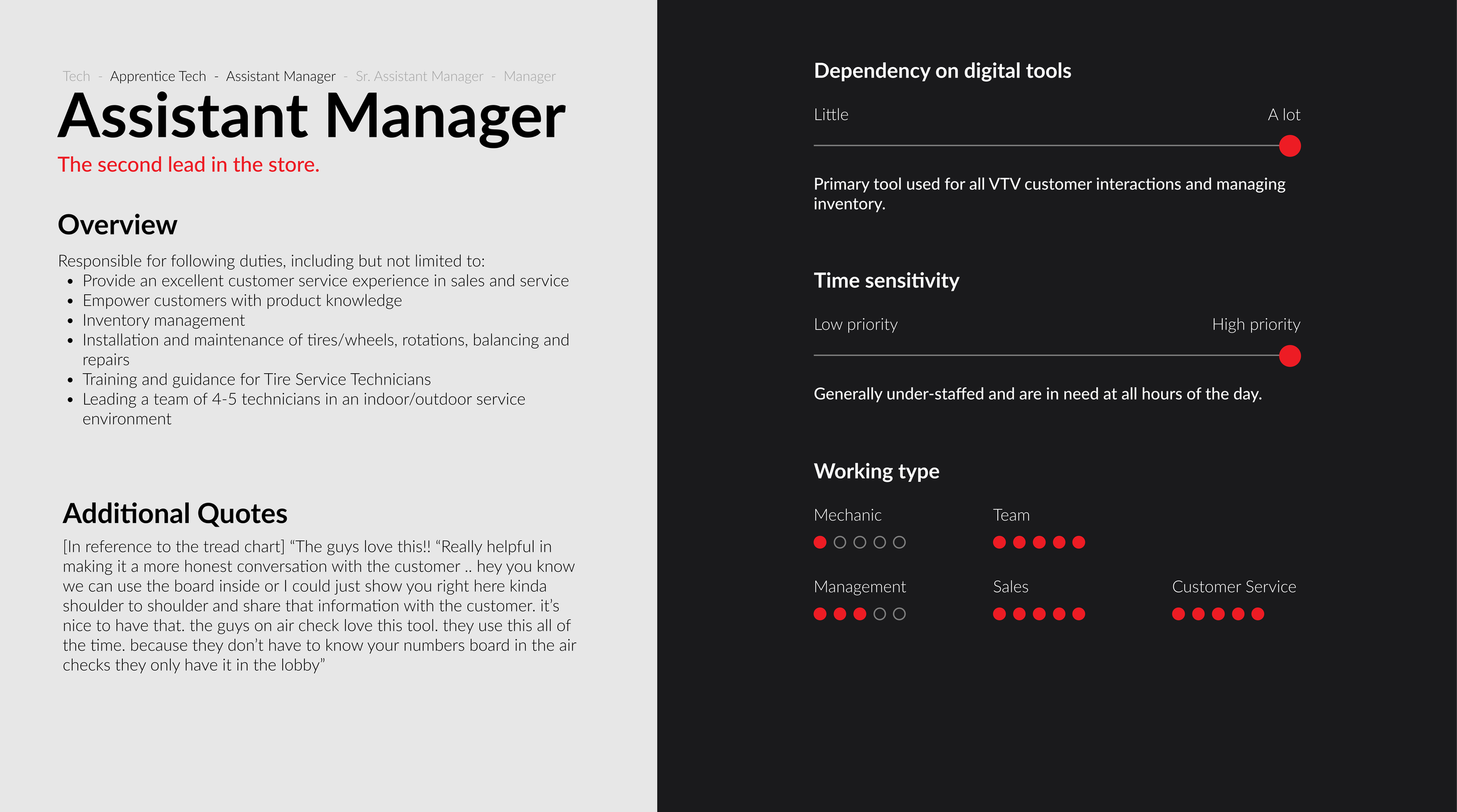

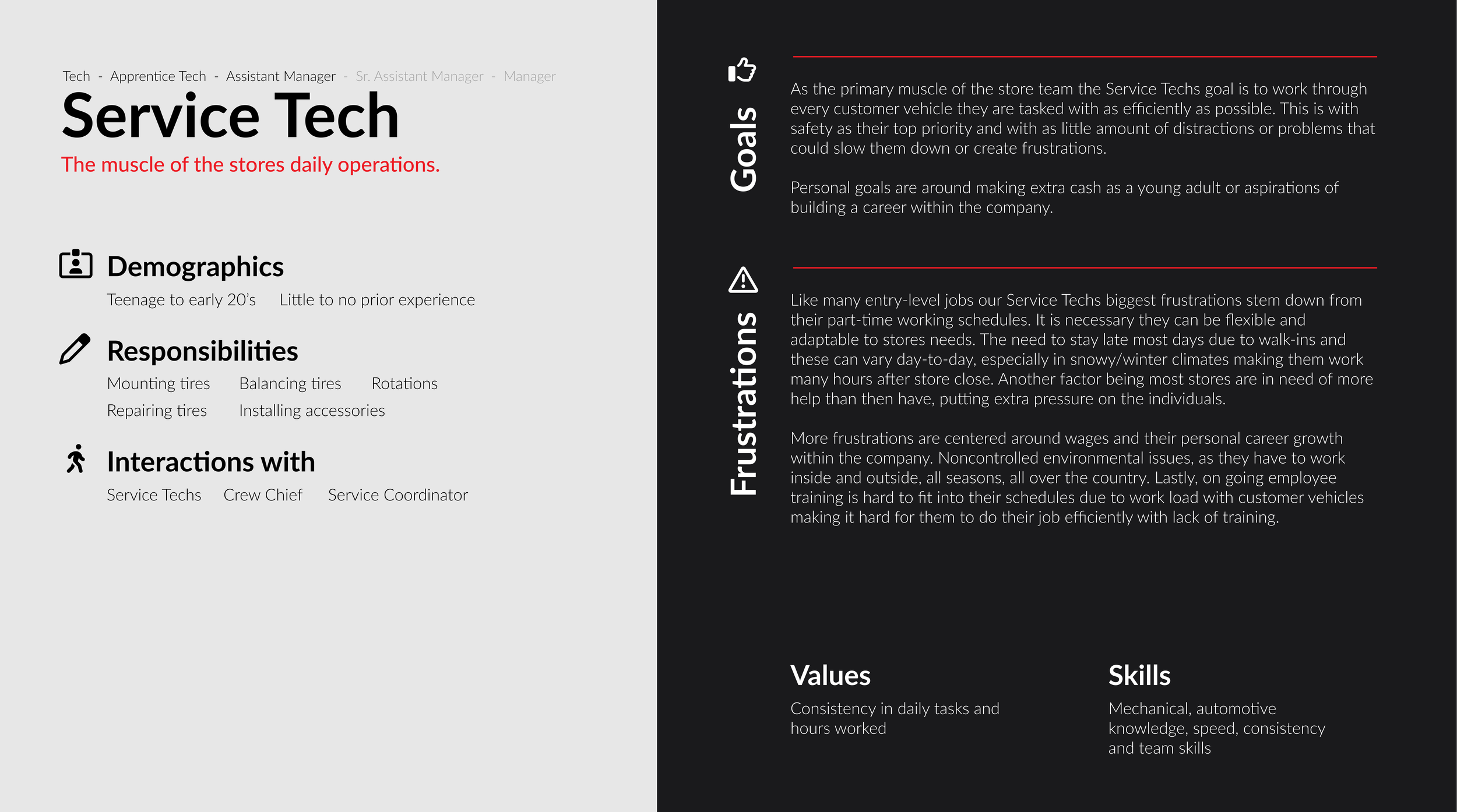

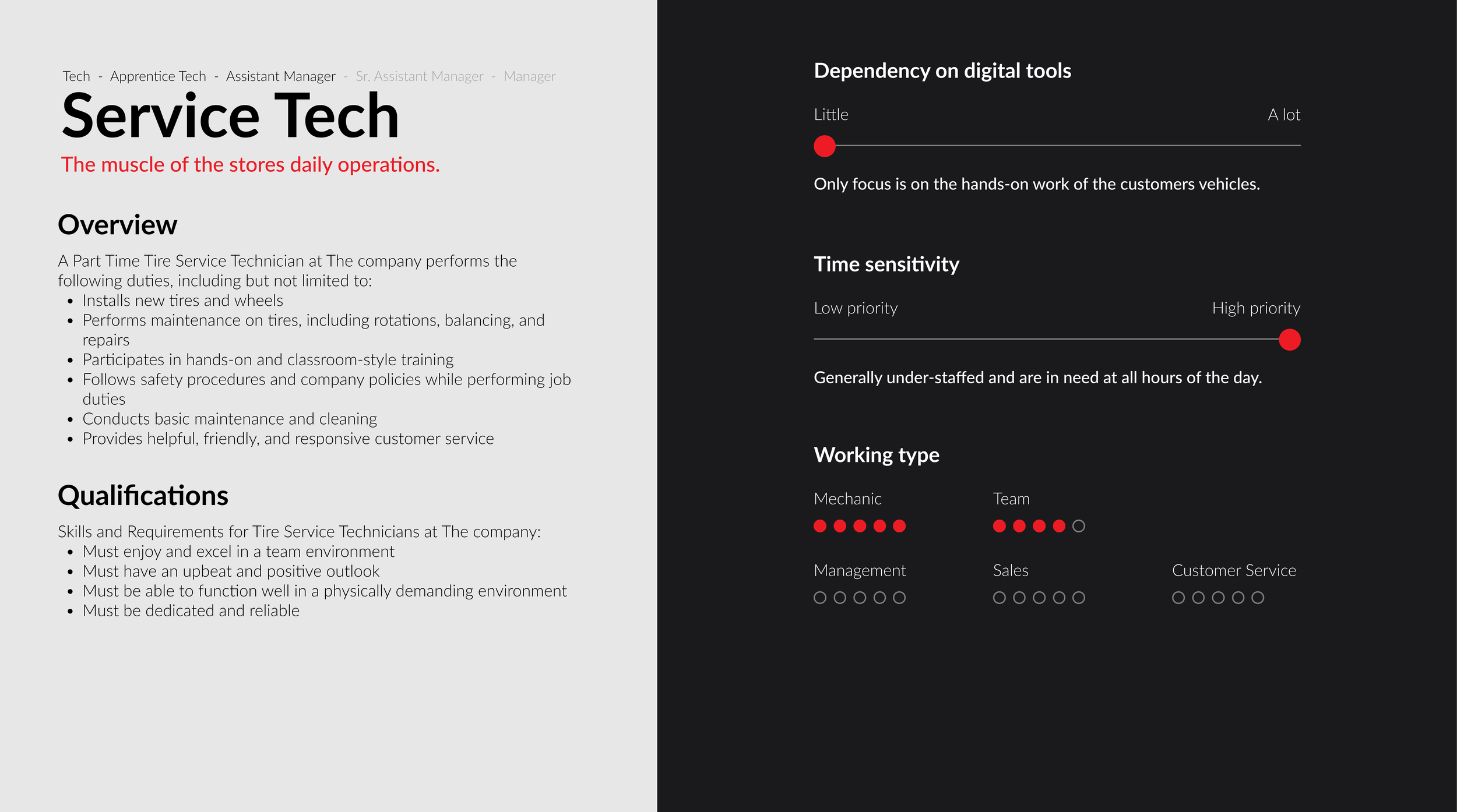

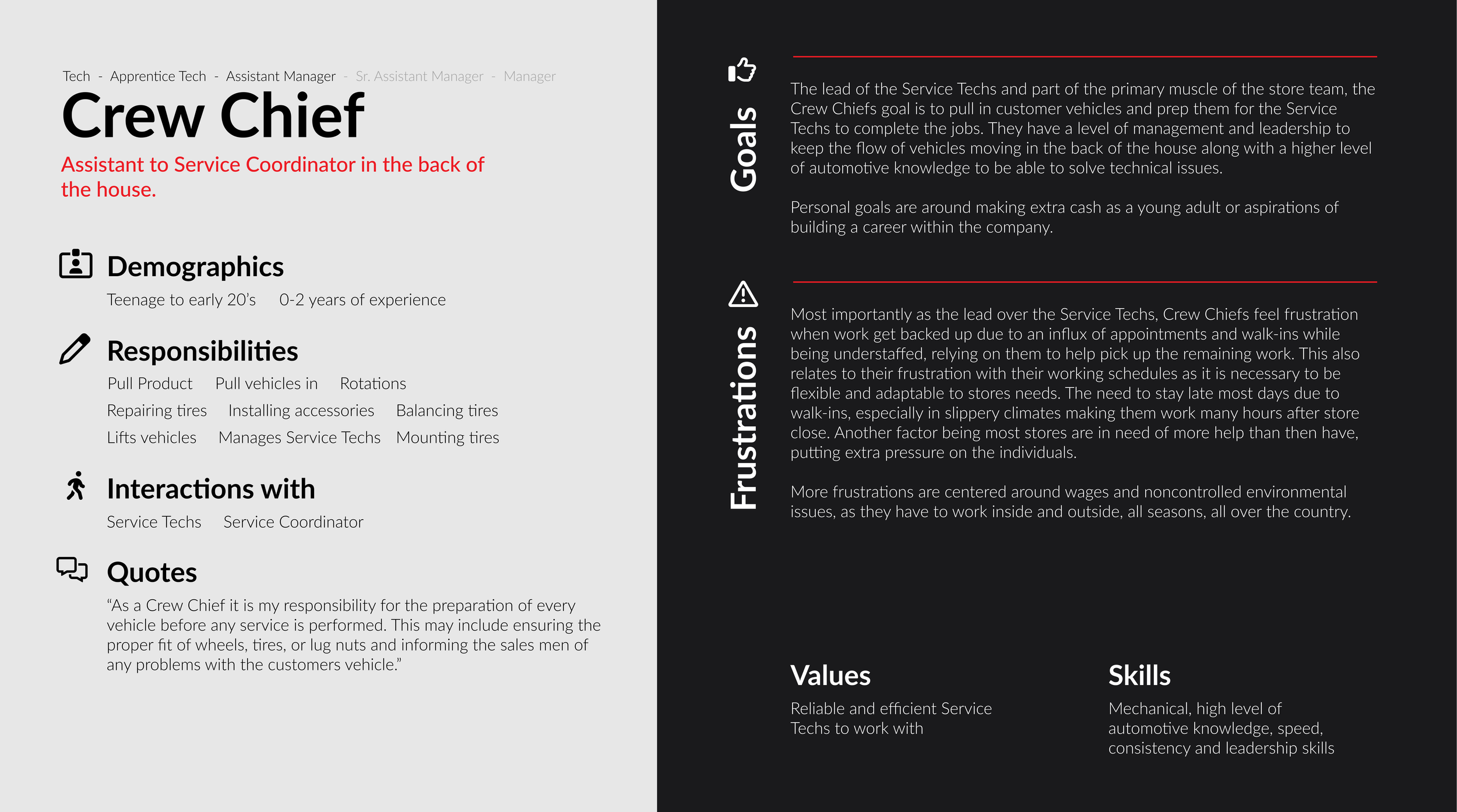

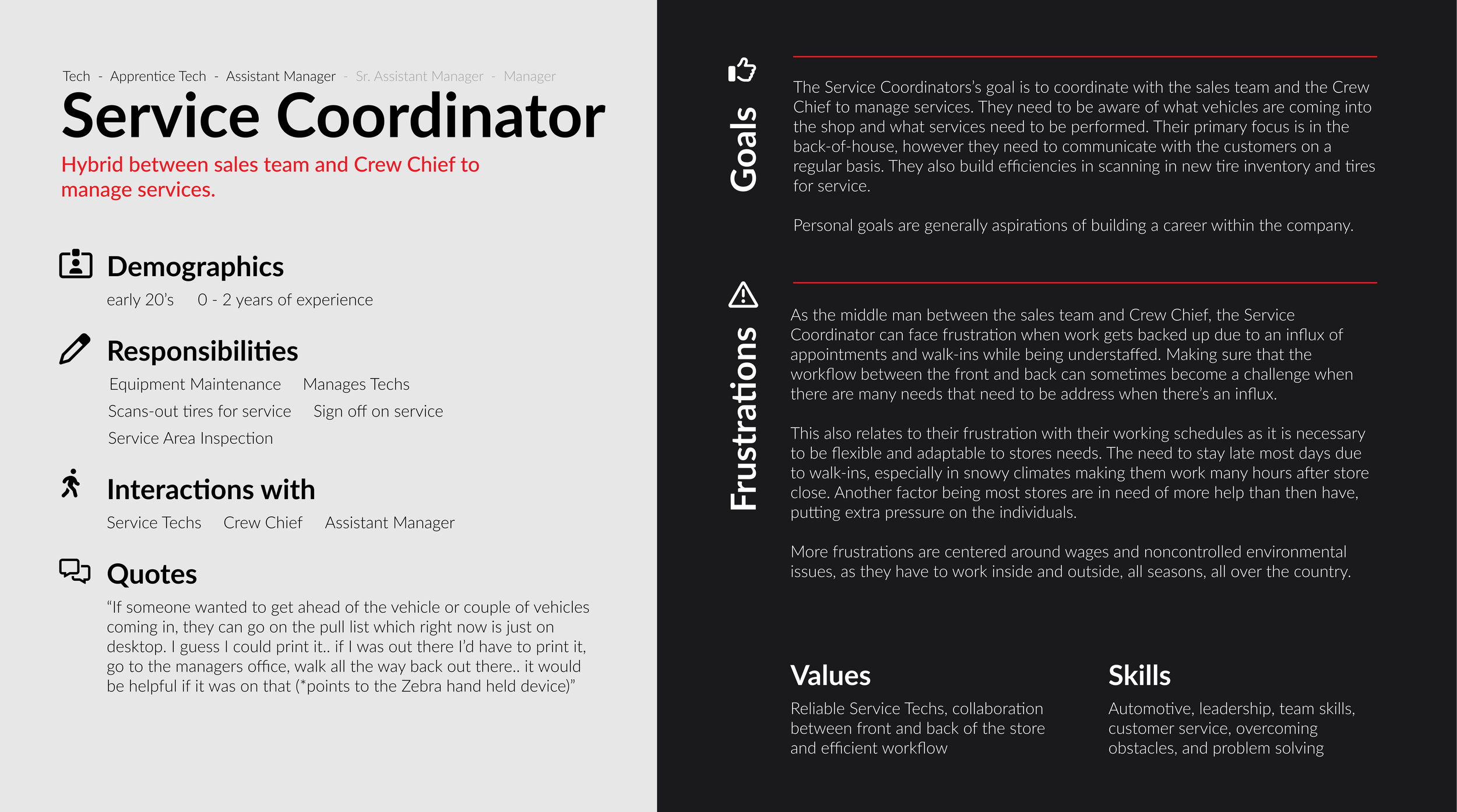

User Personas

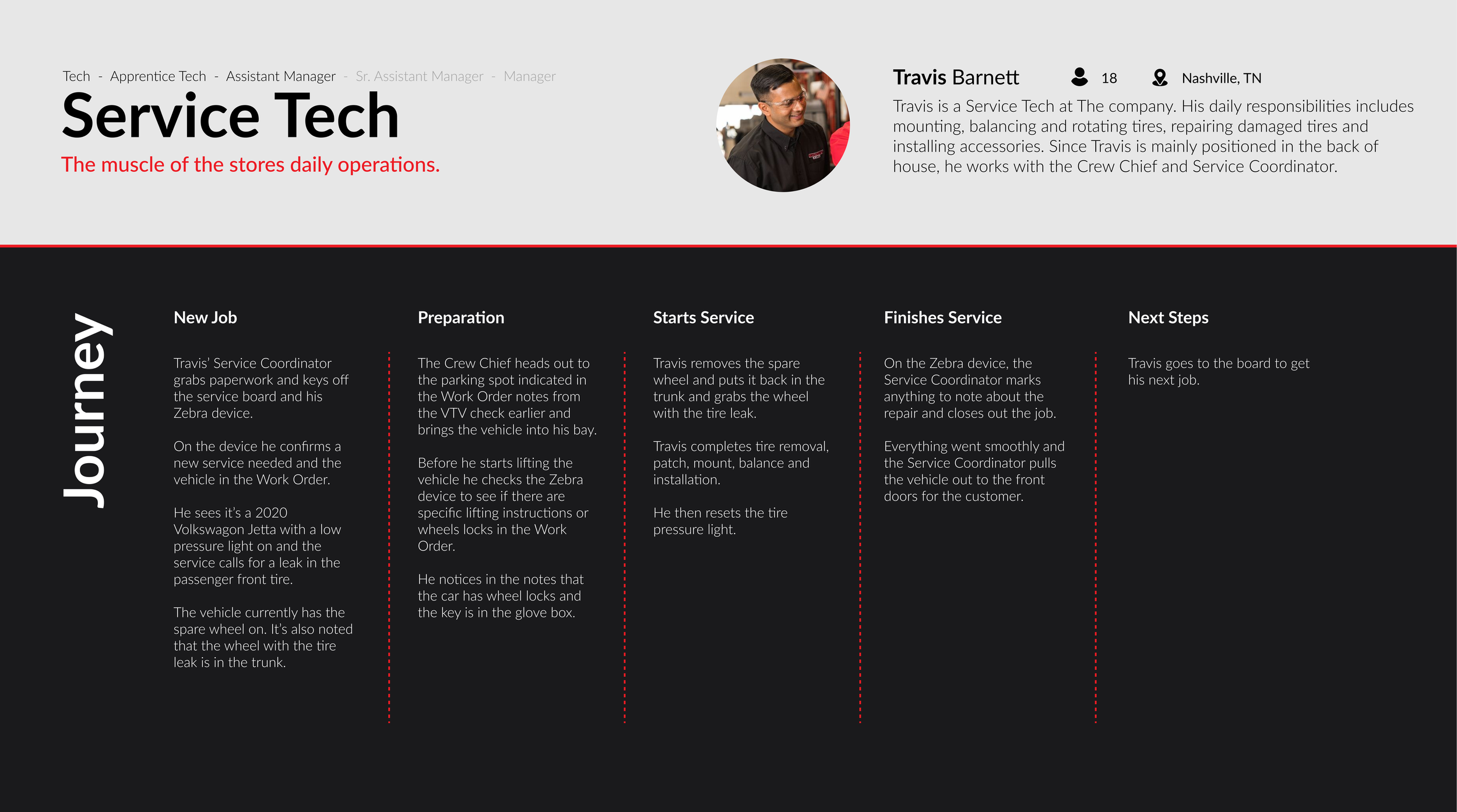

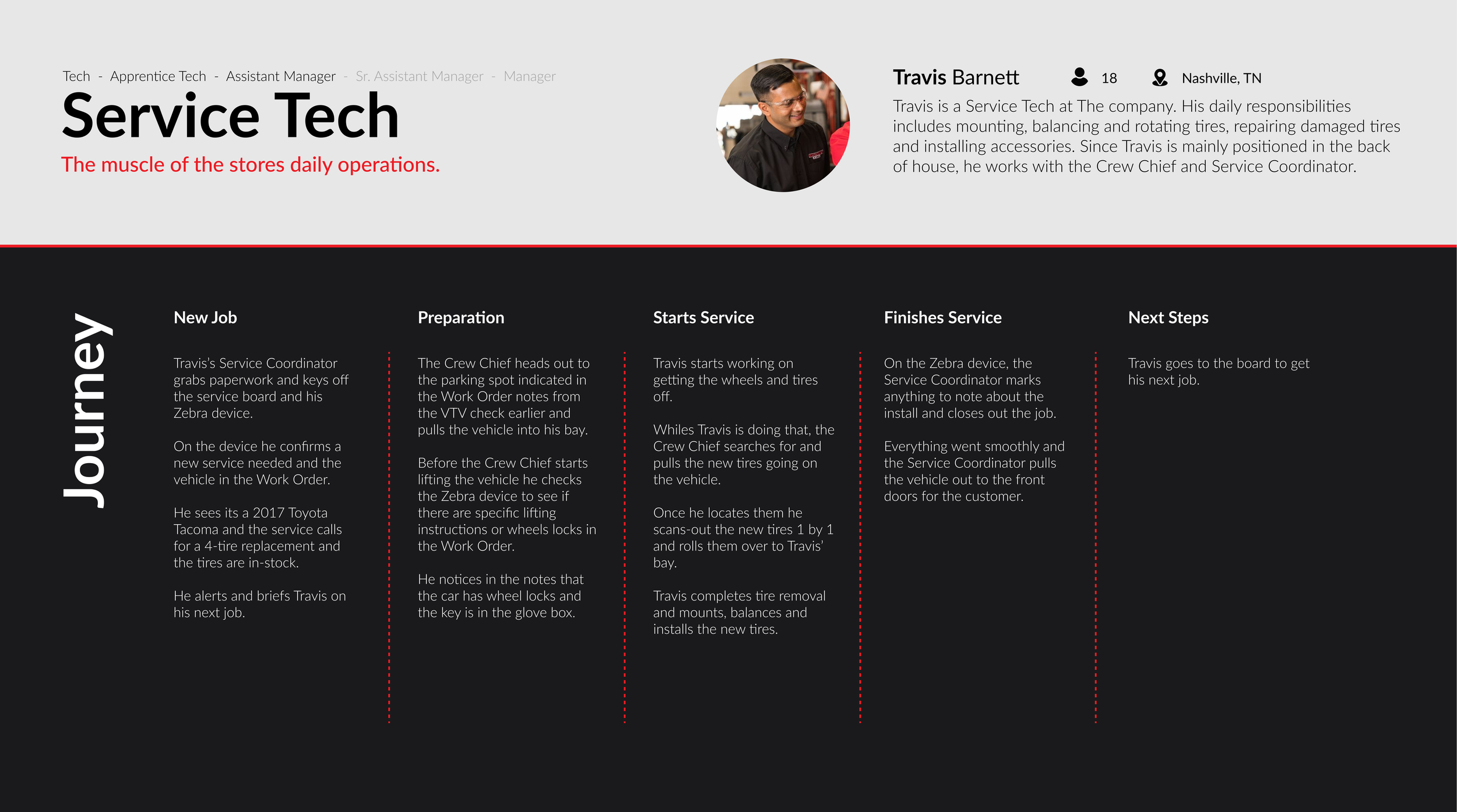

User Journeys

User Flows

Competitive Analysis

To benchmark the Work Order redesign, I reviewed leading shop management platforms that directly handle repair orders, technician workflows, and service documentation.

-

Cloud-based shop management platform focused on real-time work orders, parts, and technician workflows

Strengths: Intuitive digital repair order system, real-time visibility, parts/service tracking

Gaps: Designed primarily for independent/medium shops, not enterprise rollouts

-

Legacy repair order (hence the name) management software, focused on repair documentation and parts

Strengths: Well-known in the industry, established RO management features

Gaps: Legacy UI, less mobile support, slower to modernize

-

Longstanding auto repair software used for repair orders, estimating, and service documentation

Strengths: Trusted industry brand, robust estimating + RO tools

Gaps: Outdated design, weaker mobile experience, longer onboarding curve

-

Modern shop management system with digital repair orders, digital vehicle inspections, and reporting

Strengths: Clean interface, supports technician updates, strong reporting

Gaps: Can feel heavy in high-volume chains, enterprise scaling less proven

Key Takeaways

Editable work orders are still rare: Many tools offer repair order tracking but lack seamless in-bay, real-time editing.

Mobile-first work order management remains a competitive gap, especially for large retail chains.

UI modernization is inconsistent — most competitors still feel legacy-heavy, slowing adoption and training.

Enterprise scalability is limited; many solutions focus on independent shops rather than multi-store, high-volume environments.

Integration across tools is often fragmented, making end-to-end workflow harder to manage.

Create & Evaluate

Desktop

Before & After

Before: Legacy POS

The legacy work order was static, non-editable, and text-heavy. It slowed down service documentation and created errors because technicians couldn’t update details directly.

-

Staff had no way to update service details in real time. Notes had to be handwritten or re-entered later, causing inefficiencies.

-

Key information like vehicle status, tire data, and DOT codes were missing or buried in text-only screens.

-

Technicians relied on paper notes and re-entry at checkout, increasing the chance of mistakes.

Mid-Project:

Mid-fidelity Desktop POS

Mid-fidelity mock-ups introduced editable fields, grouped sections, and clearer flows. The goal was to create an interactive work order with reduced redundancy.

-

Early prototypes allowed staff to update customer, vehicle, and service information directly in the app.

-

Grouped information (customer, vehicle, services, VTV diagram) into logical sections to support technician flow.

-

Defined progress states like Waiting, In Bay, and Complete to help track job progress.

After: High-fidelity Desktop POS

The final design transformed the work order into a modern, interactive dashboard. It gave technicians and associates one place to manage services from start to finish.

-

Customer info, service items, and vehicle details live in one view, reducing context switching.

-

Visual input for tread/DOT data entry reduced errors and standardized documentation.

-

Smart defaults, validations, and structured fields ensured accurate, real-time service capture.

Mobile

Before & After

Before:

No Legacy POS Mobile Equivalent

Work orders were only available at desktop POS stations. Technicians couldn’t update tasks or capture data on the service floor.

-

All service updates had to be made at the desktop, slowing technicians down.

-

Tire and DOT data had to be written down, then re-entered later at desktop.

-

Delayed entry often meant missed or inconsistent documentation.

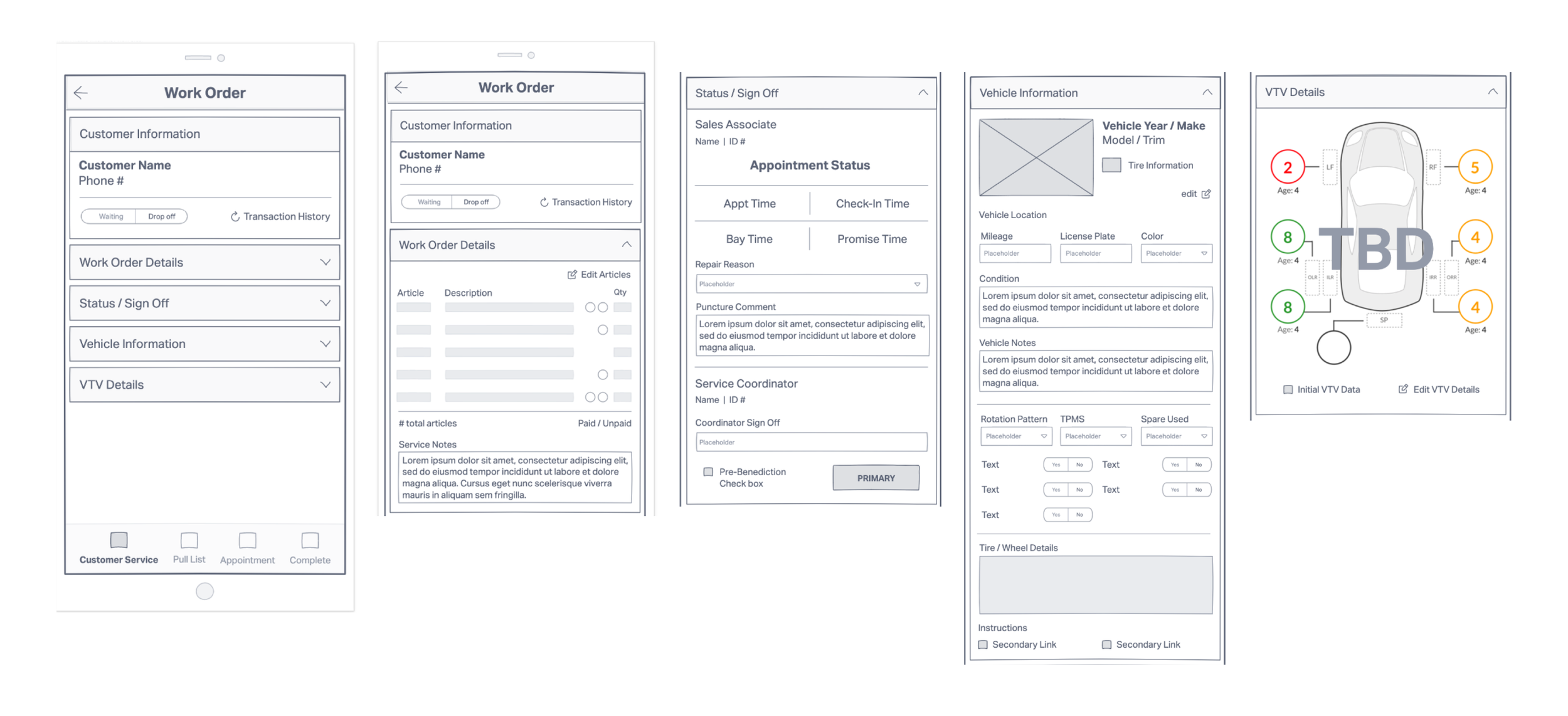

Mid-Project: Mobile Wireframes

Wireframes explored how technicians could interact with work orders from handheld scanners.

-

Designed screens for updating service status, notes, and key order details.

-

Large buttons and simplified inputs supported glove use and rugged environments.

-

Early testing with technicians refined which fields were critical in a mobile-first context.

After: High-Fidelity Mobile POS

The mobile version extended work order functionality onto rugged devices, enabling updates from the parking lot to the bay.

-

Technicians can update status, mark services complete, and capture tread/DOT data without leaving the vehicle.

-

Mirrors desktop structure for easier adoption while optimizing for touch and mobility.

-

Built to support expansion as mobile adoption grows, ensuring continuity with the full Work Order Management Suite including Product Pull List and Completed Vehicles List

Evaluate

In this phase, I pushed for structured checkpoints to validate and refine our work. One key practice was Design Day a biweekly, three-hour working session that brought together all major stakeholders from UX, Product, Engineering, and the Store Experience team.

These sessions created space to walk through flows, surface usability issues, and refine both designs and requirements in real time. By including the Store Experience team, we ensured every decision reflected field realities and the needs of technicians. This collaborative evaluation reduced rework downstream and gave the entire group a shared sense of ownership in the solution.

Results

Currently in the Implementation Phase

Reduced complexity: Editable fields streamlined service updates that were previously paper-based.

Improved accuracy: Structured inputs and validations reduced errors in tire/DOT data capture.

Faster turnaround: Technicians can update and close work orders in real time, eliminating re-entry delays.

Connected ecosystem: Application integrates with Customer and Service List, Product Pull List, and Completed Vehicles List for a seamless end-to-end service lifecycle.

Mobile impact: The introduction of the upcoming mobile Work Order has already shown strong results in usability testing at the stores, allowing technicians to update status, capture tread/DOT data, and complete tasks directly at the vehicle. This has the potential to increase workflow speed and accuracy while reducing congestion at service counters.

Enterprise rollout: The desktop Tire Service platform is now live in 546 stores as of August 2025, supporting 25,000+ employees across 1,100+ locations, with phased mobile deployment underway.